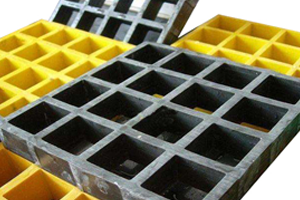

Corrosion resistance: FRP pultrusion grille has excellent corrosion resistance performance, different levels of acid, alkali, organic solvents and salt, and many other corrosion of gas and liquid medium, because of its rich resin on the surface of a molded grating is low, so the molded grating is slightly worse than its decay resistance performance. According to the practical application requirements, can choose to use economically o-type, between benzene, vinyl resin base material. Light weight, high strength, FRP pultrusion grille is will and continuous glass fiber mat, such as surface mat reinforced material by the pultrusion resin infiltration heat. High glass fiber content (60%) makes it a one-way than intensity and stiffness is quite prominent. Oxygen index of flame retardant: general FRP pultrusion gridiron over 33, the flame propagation rate (according to ASTM E - 84 testing) < 25, as the flame retardant grade, and get the American bureau of shipping (ABS) approval. Phenolic pultrusion grille oxygen index (GB8924) reached 100, ASTM E - 84 test flame propagation speed is 5, smoke density of 10. Resistance to impact and fatigue resistance, and molding FRP pultrusion gratings with high impact strength, allowing repeated bending without permanent deformation; With moderate elasticity that enables the long-term work in the above feels comfortable. Skid: FRP pultrusion grating surface linear antiskid groove design in advance, also can be spread by binder sand extra prevent slippery effect. Ageing resistance: FRP pultrusion grille to choose high quality resin, glass fiber system manufacturing, ensure the service life of the products in more than 20 years. Although after atmospheric exposure, appearance change, but twenty years later strength can still remain in the more than

Glass fiber reinforced plastic grille features and product application

May 22,2023

You May Also Like

Send Inquiry

Latest News